Roof-Lines eNews

The intersection of steel and concrete

Although they serve vastly different purposes, bridges and multistory construction are often built using systems that are quite similar in many ways

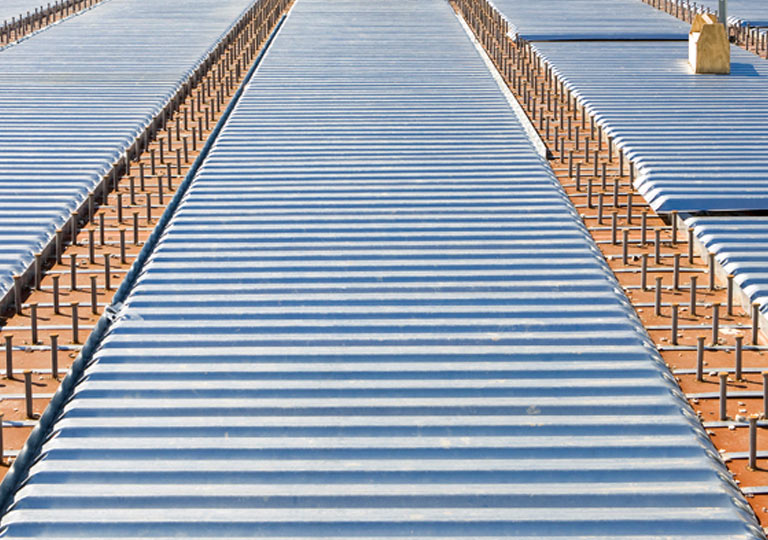

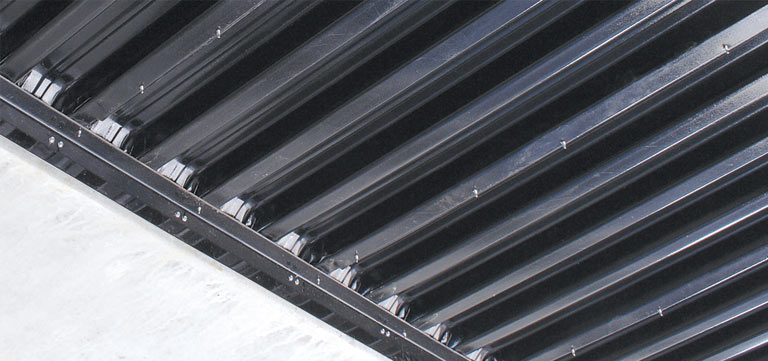

Deep-Dek® Composite, left, and Bridge-Dek® not only look very similar, they also have similar attributes that help them achieve their respective structural goals.

On their face, bridges and multistory construction projects appear about as dissimilar as can be. Upon closer—and much deeper—examination, however, they’re not so different.

Looking past their obviously distinct appearances and functions, bridges and multistory projects often have similar structural and design demands. They require different steel-and-concrete systems to meet those needs, but the systems themselves share basic traits that allow them to achieve the goals of their respective applications.

Bridge-Dek® and Rhino-Dek® are used in new bridge construction or rehabilitation while Deep-Dek® Composite is often the system of choice for thin-slab multistory construction. They all have hallmark benefits that include ease and speed of construction, safety, and durability and longevity.

|

|

Smooth, swift construction

Many factors play a part in keeping a project of any kind on schedule. Some of them cannot be controlled, such as weather conditions. But the choice of building materials is in the hands of a project’s design team and can greatly affect speed and ease of construction.

That was the case at Saratoga Race Course in Saratoga Springs, N.Y., where officials broke ground on a new three-story, 36,000-square-foot trackside clubhouse in September 2018. The 1863 Club would need to be finished before the 2019 horse-racing season kickoff on July 11, an ambitious deadline by any standard. MLB Construction Services, the project’s local general contractor and one of the oldest in the Saratoga Springs area, expects to meet the project’s deadline with the help of New Millennium Building Systems.

For the clubhouse’s floors, New Millennium was called in to provide Deep-Dek® Composite deck built on DIVERSAKORE® beams. The Panelized Delivery Method™ (PDM), which offers the advantage of assembling floor panels on the ground, was used for the Deep-Dek® panels. Marty Williams, Design Development Manager at New Millennium, says that significantly expedited the building’s erection.

“Crews were building panels, stacking them, and then awaiting their placement on the frame,” says Williams, who noted that a mild winter allowed for the building of panels without delay. “Anything you can do to get that done in advance and not have to move laborers up and down the frame certainly helps from an installation standpoint.”

Photo credit: MLB Construction Services

On-the-ground panel assembly is less affected by weather and saves time and energy because workers aren’t moving equipment between floors. Projects facing tight schedules benefit from the Panelized Delivery Method™.

The overall light weight of Deep-Dek® Composite is perhaps its greatest contribution to efficient erection, but that benefit is realized near the end of a larger process. Williams says the groundwork for a project that meets its deadline begins behind a desk: scheduling the production, drawing approvals, coordinating manufacturing and purchasing of materials, and more must go smoothly to avoid delays.

“There are a lot of steps that need to happen internally for these jobs to deliver on time and keep them on schedule,” Williams says.

Staying on schedule also is incredibly important for bridge projects that affect high volumes of vehicular traffic and sometimes marine traffic on waterways below. Bridge-Dek® and Rhino-Dek® stay-in-place form systems from New Millennium can shorten a project’s timeline. Their main advantage? Eliminating plywood forms commonly used in bridge construction. Building wood forms to hold poured concrete and then removing them requires time-consuming — and costly — manual labor.

“When you think about the labor involved to build the plywood forms and then strip them back out when the concrete has cured, the installed cost of the metal deck is less,” says Gerald Arvay, New Millennium District Sales Manager.

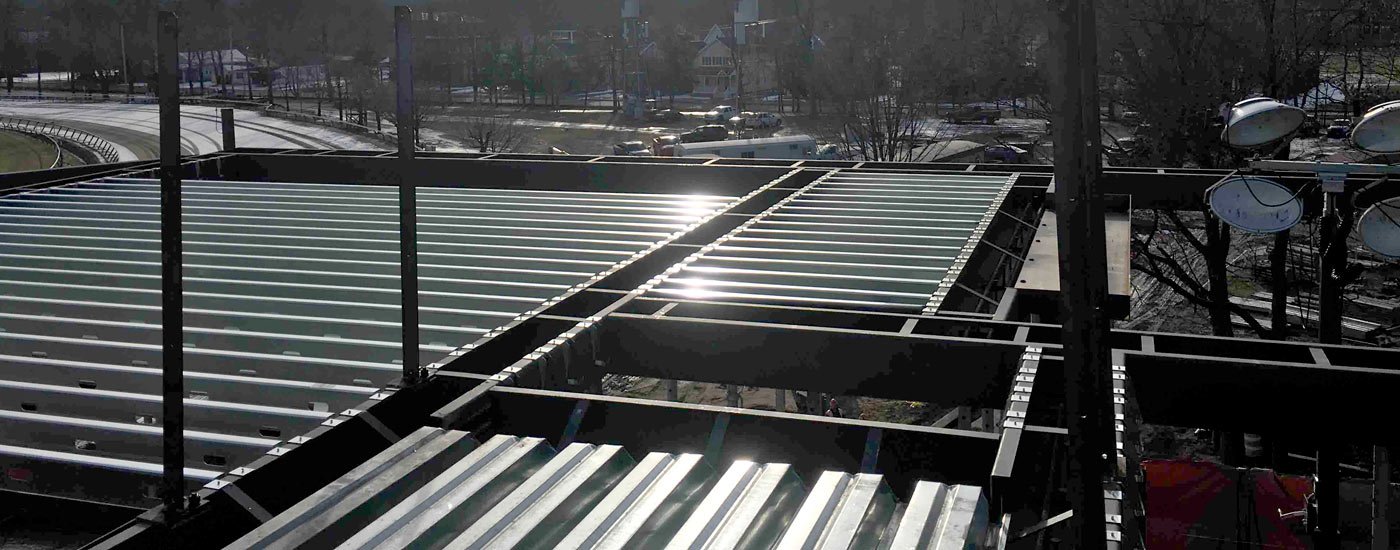

The Bridge-Dek® stay-in-place forms being used in the construction of Valley View Bridge in Cuyahoga County, Ohio, eliminate the need for laborers to go under the bridge to tear out wood forms after the concrete has cured.

Photo credit: Ohio Department of Transportation

New Millennium is supplying Bridge-Dek® for the reconstruction of the Interstate 480 Valley View Bridge in Cuyahoga County, Ohio. Up to 180,000 vehicles a day traverse the 4,155-foot-long bridge that sits 212 feet above the Cuyahoga River Valley and spans the river, the Ohio and Erie Canal, CSX rail lines, and several roadways. On a project of that scale and complexity, using steel instead of wood forms is extremely beneficial before and after concrete is poured, says Sev Mullen, New Millennium District Sales Manager.

“Crews don’t have to get underneath the bridge to construct removable deck forms,” he says. “Then of course once they put the steel deck down, they’re not having to go back underneath and take the forms out.

“That is a big deal on this job. When the bridge is going over roadways and especially over water, they don’t have to get on a barge or a boat underneath to work under the bridge.”

For bridges that must withstand harsh conditions, Rhino-Dek® further contributes to speed of erection. Because it is polymer-coated to protect the deck from corrosive saltwater environments, Rhino-Dek® is not welded to bridge girders. Instead, it is bolted or screwed, which is quicker — and cheaper — than welding in the field.

|

Safety first

When it comes to safety, New Millennium stay-in-place form bridge systems are a success on two fronts. Bridge-Dek® and Rhino-Dek® provide safe working surfaces immediately after installation and also protect the surrounding environment from items that could fall from bridges during and after construction.

Steel stay-in-place forms have a particular advantage over wood forms during construction, Arvay says.

“If you’re removing wood forms particularly over traffic, it becomes a very dangerous operation,” he explains. “With Bridge-Dek® you’re working strictly on top of the bridge for the installation, and once it’s installed you have a safe working platform for the whole working length of the bridge.”

“It also separates whatever’s under the bridge from, say, a dropped hammer or box of bolts. It keeps things from falling through.”

“It’s a safety factor,” Mullen adds. “That’s one of our big advantages.”

The safety offered by steel extends to areas under and around bridges as well — and sometimes long after laborers have finished their work. Bridges can have a service life up to about 50 years, says Mullen, who estimates that many of the rehabilitation projects he sees involve bridges built in the 1960s and 1970s. A recent American Road & Transportation Builders Association report supports his claim. It found 47,052 of America’s 616,087 bridges are “structurally deficient” and need urgent repairs.

Aging bridges can pose hazards that could endanger unsuspecting vehicles or people below. Bridge-Dek® and Rhino-Dek® stay-in-place forms prevent this.

“If the underside of the deck does eventually start to fail and deteriorate, and you don’t have the stay-in-place steel form underneath, you’re going to have falling concrete,” Arvay says. “If you do have the steel form, spalling deck concrete is contained, and can’t fall and injure anyone.”

In multistory construction, the New Millennium Panelized Delivery Method™ provides safety for laborers. The process moves high-risk construction to the ground, where workers are not subject to dangerous heights.

With the Panelized Delivery Method™ at the 1863 Club at Saratoga Race Course, Deep-Dek® Composite panels that were 200 to 300 square feet in size were hoisted by crane onto the three-story structure’s frame. The process made the jobsite safer for laborers, who did not have to move equipment up and down the frame.

Photo credit: MLB Construction Services

At the Saratoga Race Course in Saratoga Springs, N.Y., PDM made the jobsite safer for those working on the three-story 1863 Club.

“The crews are lifting and setting the deck as panels that are 200 to 300 square foot in size,” Williams says of the Deep-Dek® Composite panels. “We take that labor off the frame and put it in a safer setting on the ground.”

After it’s completed, the Saratoga Race Course facility will have a built-in safety component in the form of the steel-and-concrete framing New Millennium used with DIVERSAKORE®. The system is UL fire rated for two hours.

“The combination of Deep Dek® and DIVERSAKORE® requires no-spray fireproofing,” Williams says. “It’s an unprotected steel frame system with a major concrete component. The concrete is what gives it its fire rating. You’re not going to spray-fireproof a concrete frame, but when it’s all steel, you need the spray.”

|

Stout service life

Built in 1960, the Pensacola Bay Bridge in Escambia and Santa Rosa counties in Florida is nearing the end of its service life. Instead of rehabbing it, Florida officials have opted to build a new bridge next to the existing structure. Rhino-Dek® from New Millennium is being used on the $398.5 million project, the largest transportation initiative in northwest Florida history. To endure the corrosive saltwater environment, the Rhino-Dek® system features a polymer-laminate coating, Arvay says. Based on evaluations over three years of testing, that coating has a 124-year service life, the Florida Department of Transportation (FDOT) concluded.

“Bridge deck is on the underside of the bridge between the girders; it is exposed to the elements. If it’s over saltwater, it’s going to be exposed to salt air, salt fog, and if it’s low enough, it’ll be exposed directly to splash from the water,” says Arvay, who adds that New Millennium is the only FDOT-approved supplier of polymer-laminate stay-in-place forming systems. “Even heavily galvanized steel can eventually rust, and salt will accelerate it. The Rhino-Dek® polymer comes between the salt and the steel on every exposed portion of the bridge deck system to extend the product life dramatically.”

“In an aggressive environment, it’s what you want to use.”

The Valley View Bridge over the Cuyahoga River near Cleveland, Ohio, will feature New Millennium Bridge-Dek® with a G235 galvanization coating in order to protect the deck from the rock salt used during the winter.

Photo credit: Ohio Department of Transportation

Bridge-Dek® also has special coatings available to extend the deck’s lifespan. For the Valley View Bridge project in Ohio, Bridge-Dek® with a G235 galvanization coating is being used, the highest level of galvanization offered. Mullen says the G235 coating protects the bridge deck from the road salt used in Ohio and other northern states during the winter. Bridge-Dek® with G165 and G210 coating also is available. The higher the galvanization, the longer the deck will last, Mullen says.

Saratoga Race Course certainly has stood the test of time. The horse-racing track hosted its first meet Aug. 3, 1863, a month after the Civil War’s Battle of Gettysburg. A year later, the track’s main grandstand was built. Saratoga’s entire grounds lie within the Union Avenue Historic District. That means any addition must fit in with the area’s appearance and seamlessly blend with the lasting legacy of the historic track. The 1863 Club under construction is no different.

New Millennium is doing its part to ensure the clubhouse is still standing in 150 years, as the grandstand can claim.

The combination of Deep-Dek® Composite deck on DIVERSAKORE® beams provides the versatility of steel with the long-lasting durability of concrete. Since the 1863 Club will house an event space, a restaurant, and luxury suites, all with dedicated areas for viewing the races, the deck had to be designed to withstand the high loads created by hundreds of people, Williams says.

In addition, a vibration analysis was conducted on the deck to identify any areas that might require reinforcement.

It all adds up to a durable structure that might be celebrating another 150 years someday.

Photo credit: MLB Construction Services

Contact one of our bridge deck or composite deck specialists to discuss your project.

Case studies

- I-75 Caloosahatchee River Bridge

- Fort Myers, Fla.

- Design team: C3TS/HDR

- Bridge length: 3,904 feet

- Rhino-Dek®

- Project awards

- Top Bridges of 2015 list: Roads & Bridges magazine

- 2016 Best in Construction – Major Bridge: Florida Department of Transportation

- Outstanding Bridge Project of 2016: Florida Institute of Consulting Engineers

When the Florida Department of Transportation went forward with plans to widen the I-75 bridge over the Caloosahatchee River, New Millennium was selected to provide polymer-coated, stay-in-place Rhino-Dek® to protect the bridge from salt corrosion. In addition, the river is home to Florida’s second largest population of manatees. The innovative decking system reduced the amount of on-site work, helping reduce interruption to the habitat and improving jobsite safety.

- 443 Greenwich Tribeca Condominiums

- Lower Manhattan, N.Y.

- Architect: ODA

- Facility: 200,000 square feet

- Deep-Dek® Composite

The transformation of this historic factory in New York’s famous Tribeca neighborhood is a breakthrough in multi-story space optimization. The innovative Deep-Dek® Composite long-span floor system preserves the original 7-story structure, built in 1883, while opening a new era in space-optimized design not achievable using deeper, conventional floor structures. By virtue of the system’s unique composite strength, floors can span up to 36 feet without supporting columns.

Subscribe to the New Millennium blog

New Millennium Building Systems ... your resource for cost- and performance-improvement knowledge.

© 2024 New Millennium Building Systems, LLC All rights reserved.